ADVANTAGE.02

"One-stop manufacturing system"

Oomori Kasei places "manufacturing" and "developing people" at the heart of its business activities. Each employee has experience in multiple processes and works closely together from upstream to downstream of manufacturing, which allows us to manufacture high-quality products from start to finish. We will introduce the work involved in each process, from receiving inquiries from customers to production and shipping.

The quality of the packaging we produce directly reflects the trust placed in Oomori Kasei, so our number one priority is to produce without any problems and meet delivery deadlines. We are sometimes asked if we can speed up delivery times, but our number one priority is to produce products of a quality that we can confidently produce to our standards. If a customer requests a sample, we have a system in place that allows us to work with the production site to consider the matter and provide a sample prototype. We hope to continue creating products that will contribute to the development of the industry.

Higher quality is being demanded every year. This is due to rising social environmental awareness and the evolution and sophistication of customers' inclusions (products). There is also a demand to produce films to even higher standards, even for films that have been produced continuously up until now. Oomori Kasei is a manufacturing company that has developed packaging together with customers. It is our joy and our mission to listen to our customers' uses and propose packaging that has the necessary functions for those uses.

Sales Department

It is rare to achieve the desired standard or quality right from the start. It takes repeated trial and error to finally come up with a standard that meets the customer's needs. Oomori Kasei's strength is that we can turn even difficult prototypes into reality with our unique speedy judgment and execution. We believe that we can develop products that meet our customers' expectations because everyone involved in each process works together while thinking about how we can make our customers happy.

In the coming age, it will be necessary to create packaging using environmentally friendly materials. How to reduce the environmental impact is also an important theme for customers. Oomori Kasei is committed to "eco-production" by focusing on reusing and recycling materials during the manufacturing process. It is our mission to create films that are not discarded and are easy to recycle. Special "melting bags" that can be melted together with the contents and used are attracting attention as a form of packaging that does not become waste.

Business Division

The difficulty with film formation is that even when making films of the same shape using the same raw materials, if the temperature, air pressure, and other conditions are different, the film will not be of the same standard. Basically, you put the raw materials into the machine and it will make the film, but rather than leaving it up to the machine, we take the time to carefully adjust it using our human eyes and senses. Our motto is to always check the film as it is being rolled up to make sure it is of uniform standard. We finish the film carefully to avoid wrinkles and variations in width.

Since we operate the machines in shifts, we communicate closely with the operators before and after us and share information to minimize production loss. We produce with as little loss as possible. To achieve this, we work as a team to reduce machine troubles and human error and produce film according to specifications. In rare cases, we are unable to produce the same specifications even under the exact same conditions as the previous time, and when we investigate and identify the cause, we feel a sense of accomplishment.

Film Division

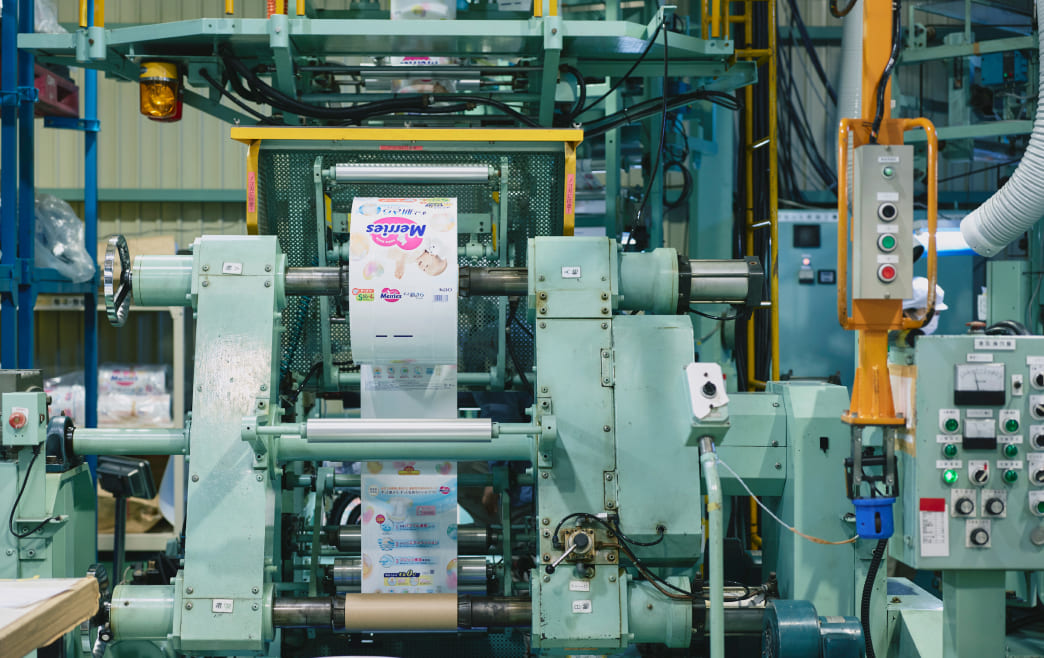

Adjusting colors is difficult without a certain level of skill. Even during the day, the first print in the morning has a light color, but as the number of prints increases, the ink gradually adheres better and the color becomes darker. At such times, the color shade is visually determined and the color tone is adjusted by lowering the printing pressure.

Samples are printed to produce the color, but the key is to adjust the sample prints as few times as possible in order to keep the printing lot running. Efficient color adjustment is essential to increasing printing speed.

We believe that the printing press has great potential. Currently, we can print up to eight colors by transferring onto the deposited film. By printing special colors, we can reproduce the customer's company logo and package design according to specifications. Our flexographic printing press is characterized by the fact that the transferred colors are less likely to shift and is equipped with a reversing machine, allowing simultaneous printing on both the front and back. A major manufacturer has been requesting package printing from us for over 10 years, and we have a consistent system in place, starting from film production.

Printing Section

The quality of the finished product changes between morning, noon, and night, so we check it thoroughly. The key is to never have one person check it alone, but to always have multiple people inspect it rigorously. If the product does not meet the standards, I make it a point to go to the deposition or printing process to find out the cause and talk directly with the operators. I think that listening to the opinions of the production site, asking about the features of the machines, and repeatedly communicating to ask "why it turned out like this" is important for quality control.

When you think of inspection, you might think of someone checking things silently by themselves, but inspections at Oomori Kasei are different. Communication is absolutely necessary for making good products. We exchange opinions with the film-forming and printing staff, and work together across departments to aim for the middle of the standard, such as making things a little thicker, to improve product quality. We check and stop production losses in the upstream process before they occur. It's rewarding to make good products that way.

Quality Control Department