PRODUCTS

About our products

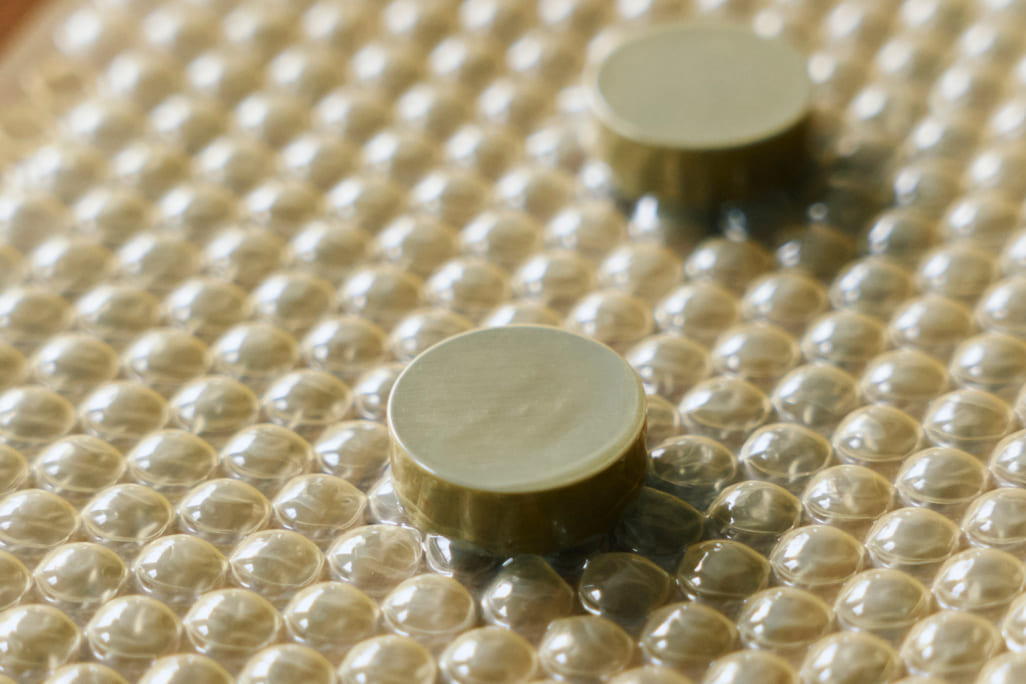

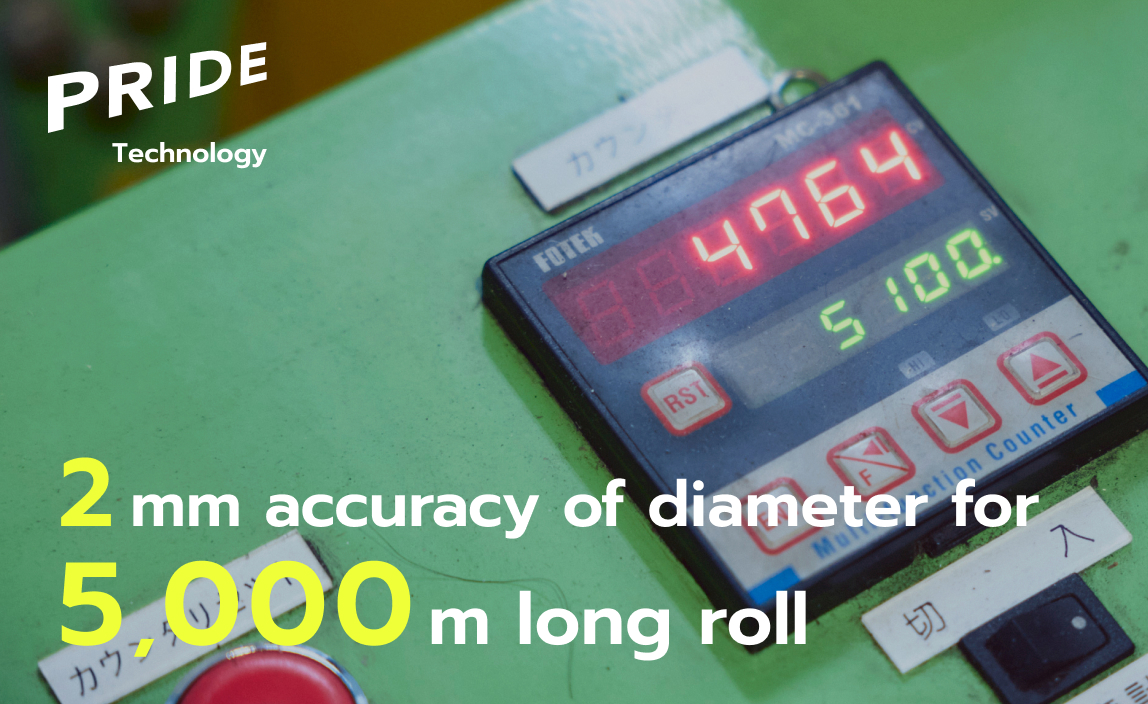

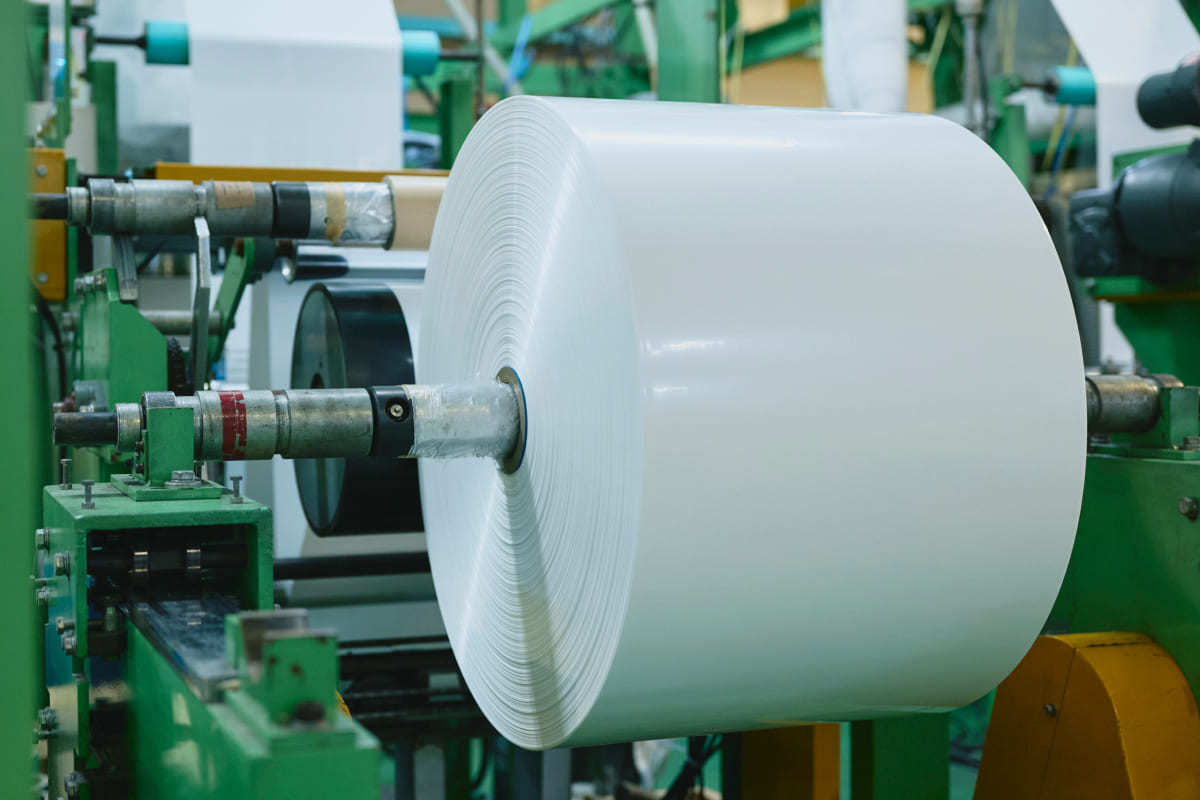

The high-performance films manufactured by Oomori Kasei are required to have various characteristics depending on the packaging applications of our customers. In addition to strength and suitability in terms of safety and health, our film manufacturing will never stop evolving, including environmental compatibility in line with the growing environmental awareness worldwide.

With the unique production technology and relentless research and management system we have cultivated so far, we would like to develop packages with new functions with a spirit of challenging anything, in response to customer requests such as "I would like to use it for this purpose" or "Other companies refused because they said it was impossible."

Other Products

Main raw materials used

LDPE

L-LDPE

HDPE

EVA

Ionomer

Polybutadiene (RB)

α-Olefin Copolymer (Tafmer)

EMMA

PP

Product

Film for newspaper packaging

Tubes for powder bags and medicine bags

Shrink film

Highly clean bags for semiconductor materials

HDPE film

Various other general packaging